What if you could customize your putter with the same options afforded to PGA Tour pros? What if you could choose from a wide menu of aesthetic choices, including finish, color and even personalized stamping? What if you could resurrect an old putter from cosmetic oblivion?

The fact is, you can—at least according to the folks at Black Oxide Service (BOS). Is it the real deal, or simply too good to be true?

Following is PutterZone.com’s review of Black Oxide Service’s putter refinishing work.

The Storyline

Black Oxide Service was founded in 1985, but the company’s story really begins in 1979, when Leo Slivnik started a machine shop in his garage in

“My parents immigrated to the

Apparently, Leo did magnificent machining work, because he was soon producing parts for the aerospace, military and other industries. Soon enough, the golf industry came knocking, too, in the form of the legendary Ely Callaway, who asked Leo to manufacture Callaway’s MF-2 hickory stick putters.

Initially, Slivnik Machining, Inc. outsourced its metal finishing work. But Leo was so disappointed in the quality of the outside finishing that he started Black Oxide Service—enabling him to not only manufacture his own industrial parts and golf clubs, but to finish them as well.

At the height of its putter manufacturing business, the company produced more than 25,000 putters annually for Titleist, Ray Cook, Cobra and others. The company was also instrumental in the development of the famed custom putter studio of designer Scotty Cameron, which was initially located just down the street.

Today, the 15,000-square-foot family business is run by Monica and her brother August. On the golf side of things, their stated focus is on world-class customer service and artisan quality. They continue to produce and finish putters for 350 Milled and others, and they also offer custom putter refinishing for individual customers.

BOS’s refinishing specialties are black oxide and “oil can” finishing, which is more iridescent or “oily” looking than black oxide (oil can finishes can only be applied to carbon steel putters). Both finishes penetrate and coat the steel of a putter. The advantage of both is that you get an elegant protective finish without build up on the parent metal, be it carbon steel or stainless steel.

“When you purchase a putter made of high-grade carbon steel or stainless steel, the feel and feedback of the putter come from that material,” Monica says. “So if you paint over that material or treat it with nickel plating, it creates material build up that diminishes the natural feel and feedback of the parent metal. It’s like buying a Ferrari, then removing the engine and replacing it with one from a Yugo.”

BOS’s refinishing customers fall into two main categories—those who have beloved putters in need of finish restorations and those who simply want to customize their putters. It is not unusual for BOS to receive a brand-new putter from a customer who simply wants it treated with a different finish.

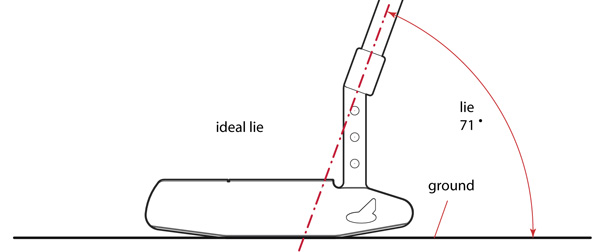

The company’s services, however, are not limited to black oxide and oil can finishes. They offer custom stamping and custom paint fills (ie: the color of a paint used on the stamped portions of a putter) as well as other finishes, such as blue torch. They can also remove dings, re-mill putter faces and even adjust your putter’s lie.

Says Monica: “As a consumer, you should be able to customize your putter any way you want. This is one of the major reasons why we started the refinishing service.”

The View from PutterZone.com

I sought refinishing for my Mizuno T.P. Mills Workshop II forged carbon steel putter. I am the second owner of this putter, and it was in rather rough shape, with a washed-out mottled black finish, several rust spots and some dings along the corners. It still had beauty on the inside, but it was in need of an extreme makeover.

Prior to making any personal contact with Black Oxide Service, I requested a putter refinishing quote via their web site, using an alternate email and not mentioning PutterZone.com. Within minutes, I received a personal email and quote from Monica. The quoted cost was $46 plus shipping ($14.45), which included custom paint filling of the words and markings on the putter.

I responded with a few more questions about the different types of available finishes. In addition to quickly answering my questions, Monica voluntarily sent a separate email with PDF attachments showing photos of their various finishes. Black Oxide Service definitely walks the talk of superior customer service.

Among the available finishes, I chose the III Black finish—which consists of a glossy sole, a satin face and a matte crown for glare reduction. My putter’s original paint fill was white, except for the word “Workshop,” which was silver. I kept a lot of the white, but eliminated the silver and added touches of yellow and red.

After the stated turnaround time of three weeks, I received my refinished putter. The transformation was remarkable (see photo above), and my expectations were exceeded. The putter looked virtually new, and perhaps even better than new with its stylish III Black finish and color enhancements. Even the dings were gone. We’re not talking about a subtle upgrade. We’re talking about going from utterly dingy to truly dazzling.

The Bottom Line

For a very fair price, Black Oxide Service can breathe new life into your old putter—or simply add style to a new one. The company is a true American success story, and the Slivnik family delivers on their promise of hands-on customer service. If your putter is becoming a frog, Black Oxide Service will turn it into a prince. Visit the Black Oxide Service web site more information.

PutterZone – Best Putter Reviews

PutterZone – Best Putter Reviews

This is awesome, I’ve been looking for a place that does this type of process. So far I only found Nomad GOlf, but they charge out the Wazoo!

so this Black Oxide Service is cool.

Vern,

Toledo, Ohio